EHEDG TRIPLE 0.8

INOXCO TRIPLE 0,8 - a complete product range without compromises

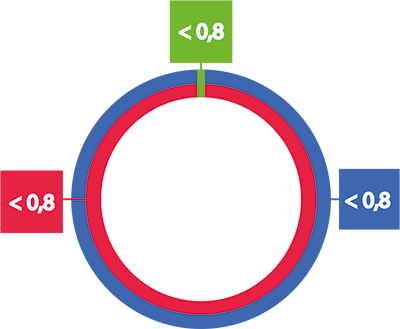

Very strict hygienic rules impede that food or pharmaceutical products become unhealthy or unsafe during the production process. Excellent cleanability of stainless steel components is key. Therefore a smooth surface of the stainless steel components that are used in the production line is required. The INOXCO TRIPLE 0.8 range guarantees an internal and external roughness and roughness on the weld area of Ra < 0.8 µm.

- Tubes and TRIPLE 0.8 fittings (Ra < 0,8 µm)

- Tubes and fittings cleanable according to EHEDG specifications

- EN10357 Series A - EN10357 (DIN 11850 Practice Based Sizes)

- Conformity statement CE1935/2004

- Internal and external roughness mentioned on the material test report (MTR)

- EN10204-3.1

- Tubes and fittings directly available from stock

|

||

|

Roughness on the weld Ra < 0,8 μm Weld factor V=1 |

Internal roughness Reduces contamination risk and improves cleanability. |

External roughness Reduces the contamination risk from outside by preventing dirt from getting a grip on the surface (for example when opening the tube). |

The inoxco TRIPLE 0,8 product range includes

|

Technical specifications

|

Only available in stainless steel 316L

INOXCO TRIPLE 0,8 tubes and TRIPLE 0,8 fittings are only available in stainless steel 316L. This austenitic chromium-nickel stainless steel quality offfers a superior corrosion and heat resistance compared to other qualities.

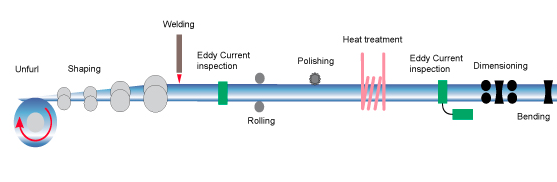

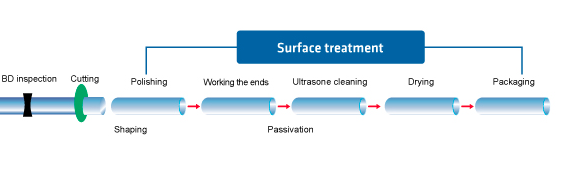

Ultrahygienic production process

The state-of-the-art production process of INOXCO TRIPLE 0,8 tubes and fittings guarantees an outstanding quality level.

Extreme traceability

- Permanent marking: heat number, dimensions, surface finish, material, execution number

- Marking both on tubes and fittings as well as on material test reports (MTRs)

Clear markings on the inoxco EHEDG TRIPLE 0.8 components and MTR (Material Test Report) ensure that the INOXCO EHEDG TRIPLE 0.8 parts are very easily traceable.

Advantages

- Complete product range: tubes and fittings

- For a safe and hygienic production according to the food-safety regulations

- Significant lower cost of ownership as a result of reduced costs for maintenance, less energy consumption (shorter cleaning cycles) and less consumption of detergents

- Extreme traceability: both marking on the component as on the certificate

- Improved cleanability thanks to the extreme surface smoothness

- Hygienic packaging and stockage

- Reduced risk of contamination and corrosion

- Directly available from stock

Other EHEDG products in our product range:

- EHEDG butterfly valve: weld/weld, weld/thread, thread/thread available both in 304L and 316L; standard EPDM seal (silicone and viton also available); 2 way-positioning handle, optionally extendable with actuator and indication unit

- EHEDG spray balls

- EHEDG conformity: membrane pump, lobe pumps, centrifugal pump