K-DisHo Kaltenbach

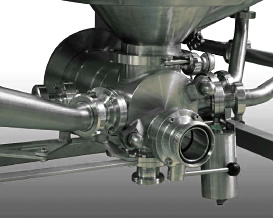

Vacuum process plants - Homogeniser K-DisHo

- Proven concept and ideal homogenisation tool for every product: DisHo

- Reduces production times by up to 60%

- Aseptic design for fast and effective cleaning

- CIP/WIP

- Optimal reproducibility

- Good de-aeration

- End-to-end automation

- Simple homogeniser - very effective

K-DisHo

|

|

|

Contact US

Belgium

T +32 3 870 60 80

advice@gillain.com

Applications

- Mayonnaises and dressings

- Ketchup and emulsified sauces

- Pasta sauces and delicatessen products

- Humus (chickpeas with tahina)

- Creams, lotions, gels

- Decorative cosmetics

- Toothpaste