Reach the highest level of efficiency.

Heating, cooling and pasteurization are extremely sensitive processes. You have to produce safely and hygienically, without affecting the quality of your products. Whether you are a brewer, a dairy or drink producer, or a food or pharmaceutical products manufacturer, Gillain & Co has the right solution for you. Our advisors translate their processing knowledge to your specific applications and determine which heat exchanger fits best for you. They take into account the following requirements:

- Avoiding dead angles (CIP)

- Easy installation

- Minimizing your maintenance time and cost

- Optimizing your production (increasing uptime)

Select your heat exchanger

| TUBE HEAT EXCHANGERS | PLATE HEAT EXCHANGERS

|

- Also known as shell and tube heat exchangers.

- In its simplest form it is a tube into another tube or a tube surrounded by a mantle.

- Usually it consists of a shell (a large pressure vessel) with a bundle of tubes inside it. One fluid runs through the tubes, and another fluid flows over the tubes (through the shell) to transfer heat between the two fluids. The set of tubes is called a tube bundle, and may be composed by several types of tubes: plain, longitudinally finned, etc.

- Two fluids, of different starting temperatures, flow through the heat exchanger. One flows through the tubes (the tube side) and the other flows outside the tubes but inside the shell (the shell side). Heat is transferred from one fluid to the other through the tube walls, either from tube side to shell side or vice versa. The fluids can be either liquids or gases on either the shell or the tube side. In order to transfer heat efficiently, a large heat transfer area should be used, leading to the use of many tubes. In this way, waste heat can be put to use. This is an efficient way to conserve energy.

|

- A plate heat exchanger consists of a number of thin, corrugated plates. These plates are pressed against each other in a frame where the edges of the plates are sealed or welded together. This way, parallel channels between the plates are created. One liquid is led by the even channels, while the other fluid is led by the odd channels. If there is a temperature difference between the two fluids, the heat of the hot fluid is transferred through the plates to the colder fluid.

- In comparison with a conventional heat exchanger, the fluids are exposed to a much larger surface area because they are spread out over the plates. This facilitates the transfer of heat, and increases the speed of the temperature change.

|

Discover our heat exchangers

Tubular heat exchangers - pharma

Tubular heat exchangers - food

Plate heat exchangers - gaskets

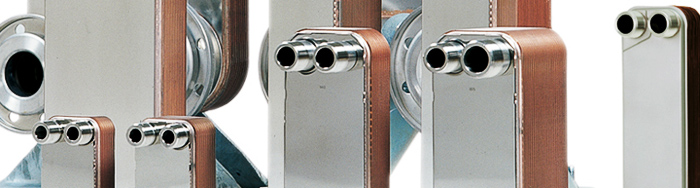

Brazed plate heat exchangers

Fusion bonded heat exchangers